MIL-DTL-22992 Class L Connectors

MIL-DTL-22992 Class L connectors are heavy duty, IP67 rated, power connectors built to withstand the rigors of power distribution applications for the most demanding military applications. Connectors are designed with current-specific ratings ranging from 40 to 200 amps and incorporate various safety features to protect equipment and personnel.

MIL-DTL-22992 Class L connectors are built in specific configurations prescribed by MIL-DTL-22992 for either military or industrial applications. This type of connector is required for all ground power equipment by MIL-STD-454, and are considered the preferred connector under MIL-STD-1453, which mandates its use in all equipment procured by the military. This rigid configuration control ensures correct interconnection of electrical circuits for maximum personnel safety and ultimate reliability.

MIL-22992 Class L connectors are the Rolls-Royce standard for military and heavy industrial power built with personnel safety and protection in mind.

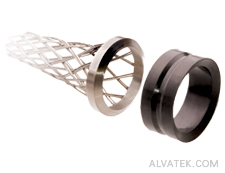

In particular, shell style and contact type are specified for safe installation. Wall mount and cable connecting receptacles are supplied with socket contacts only and always lead from the power source. Plugs (with coupling rings) only have pin contacts and always lead to the equipment end. Shell sizes are directly related to the current carrying capability of the connector, which reduces the possibility of inadequate wiring for heavy electrical loads.

Basic Characteristics of the MIL-DTL-22992

- Safe and reliable power connectors

- Current range from 40 to 200 amps

- Heavy-duty shell design for harsh environments

- Automatic grounding and arc quenching design for safety

- Direct current or single/three phase, 60/400 Hertz AC

- Double stub coupling threads for fast reliable coupling

MIL-DTL-22992 Class L Connector Resources

MIL-DTL-22992 Class L Connector Shell Styles

MIL-22992 connectors are built to withstand harsh environments and are IP67 rated. Aerospace-grade alumium shells provide heavy-duty protection while a standard olive drab cadmium finish provides excellent corrosion resistance. Four available connector shell styles provide design flexibility for modern power distribution.Select your preferred shell style from the list below:

MIL-DTL-22992 Class L Accessories

MIL-DTL-22992 Class L Tools

MIL-DTL-22992 Class L Specifications

- MIL-DTL-22992 Class L Approved

- Shell Styles

- 4 Shell Styles: Cable Plug, Wall Mount Plug, Wall Mount Receptacle, Cable Receptacle

- Shell Sizes

- 4 Shell Sizes are available, size 28-52

- Contact Sizes

- 4 Available (#6, #4, #4/0, #1/0, Accepting 6 to 4/0 AWG)

- Contact Plating

- Silver Alloy Plate, .0002 in (.0051 mm) Minimum

- Max Contact Resistance

- Potential Voltage Drop

- Current Rating

- 200 Amps (Rated Current) at 68°F (20°C) for Inserts 52-12 and 52-13

- Max Operating Voltage

- 2,000 VAC (RMS) at Sea Level

- Grounding

- Automatic, Grounding and Neutral Contacts Have Mate First/Break Last Design

- Arc Quenching

- Recessed Socket Contacts Within Insert Create an Arc Suppression Chamber for Safety

- Insulation Resistance

- >5,000 Megohms at 77°F (25°C)

- Heat Rise

- Temperature Rise of Individual Contacts Will Be No More Than 54°F (30°C) Above Ambient Temperature

- Air Leakage Rate

- Environmental Connector Air Leakage Rate Shall Not Exceed 1 Inch 3/hr (4.55 x10-3 cm 3/sec) at 30 psi (2.11 kg/cm2) Pressure Differential

- Humidity

- Mated Connectors Shall Maintain an Insulation Resistance of 100 Megohms or Greater at 77°F (25°C) With 95% Humidity for Duration of 20 Days

- Polarization

- Single Master Key, and 4 Minor Keys

- Operating Temp

- -67° to +257°F (-55° to +125°C)

- Environmental Rating

- IP67 Rating (Environmental Sealing)

- 500-Hour Salt Spray Rating (With Olive Drab Cadmium Finish)

- Chemical Resistance

- 20 hour full immersion (unmated) in hydraulic fluid and lubricating oil without damage or material degradation

- Coupling

- Threaded, Double-Start Stub Threads, 2¼ Turns to Couple With Knurled Coupling Ring

- Contact Arrangements

- 7 Standard Inserts Available

- Coupling Cycles

- 250 Coupling Cycles (Minimum)

- Shock

- 50g’s, 11ms Duration, Three Major Axes, 10 Microseconds Maximum Discontinuity

- Vibration

- Random Vibration at 10 to 2,000Hz (15g’s), 10 Microseconds Maximum Discontinuity

- Shell Conductivity

- Maximum Shell-to-Shell Conductivity Potential Drop Less Than 200 Millivolts Across Assembly, and 400 Millivolts After Conditioning Across the Assembly

- Insert Assembly

- Plastic Dielectric, Removable

MIL-DTL-22992 QPL Information

- Title

- Connectors, Plugs and Receptacles, Electrical, Waterproof, Quick Disconnect, Heavy Duty Type, General Specification.

- Scope

- This specification covers multi-contact, heavy duty, quick disconnect, waterproof, electrical plug and receptacle connectors and associated accessories for electronic and electrical power and control circuits. Connectors are rated for temperatures between -55 Degrees C to +125 Degrees C. See 6.1 for intended use and applications.

- Status

- Active

- Active Document Date

- 28-DEC-2015

- Next Review Due

- 26-DEC-2020

- FSC/Area

- 5935

- Next Review Due

- 26-DEC-2020

- MIL-DTL-22992 QPL

- MIL-DTL-22992 Class L QPL Document Rev. H

MIL-DTL-22992 QPL Approved Manufacturers