About MIL-DTL-26482 Series 1 Crimp Connectors

MIL-DTL-26482 Series 1 crimp connectors combine high-performance reliability for military and industrial interconnect applications. The series features heavy-duty connectors with crimp contacts and bayonet or “quick-disconnect” coupling.

MIL-DTL-26482 features bayonet “quick-disconnect” coupling, making connecting and disconnecting quick and easy!

MIL-DTL-26482 Series 1 crimp connectors are rated to IP67. Environmental sealing is achieved with a grommet and clamp design. Operating temperature for the connectors is from –55° to +125°C. Operating voltage is 1,000 VAC (RMS) at sea level.

The series offers pin and socket crimp contacts that are machined from low-loss copper alloy and are gold plated to eliminate contact corrosion and provide an indefinite shelf life. All connectors have resilient inserts that provide high dielectric strength and a good moisture barrier. A variety of shell finishes (including non-cadmium) and a variety of accessories are available to ensure interconnect reliability.

Basic Characteristics of the MIL-DTL-26482 Series 1

Basic Characteristics of the MIL-DTL-26482 Series 1

- IP67 environmental rating

- Crimp contacts

- Bayonet “quick-disconnect” coupling

MIL-DTL-26482 Series 1 Crimp Connector Resources

MIL-DTL-26482 Series 1 Connector Shell Styles

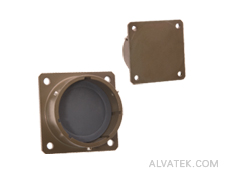

MIL-DTL-26482 Series 1 crimp connectors are IP67 rated for applications in harsh environments. Aerospace-grade aluminum shells provide heavy-duty protection while a standard olive drab cadmium finish provides excellent corrosion resistance. Alternate finishes (including RoHS) are available.

Select your preferred shell style from the list below:

MS3124

Jam Nut Receptacle

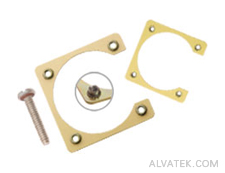

The MS3124 jam nut receptacle provides increased environmental protection due to its single mounting hole design. An integrated silicone O-ring offers additional sealing. A protective backshell is recommended if the connector is subjected to environmental hazards. A cover should be used to protect the contacts from damage.

MS3121

Cable Mount Receptacle

MS3121 in-line or cable mount receptacles are used for extension cord applications. A reduced flange with rounded corners protects the connector from impact when the attached cable is dragged or dropped. A protective backshell is recommended if the connector is subjected to environmental hazards. A cover should be used to protect the contacts from damage.

MS3127

Wide Flange Box Mount Receptacle

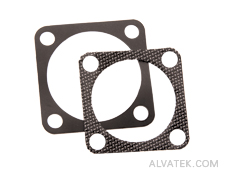

The MS3127 box mount receptacle offers a wide flange for secure back-panel mounting, in addition to a low-profile rear end without accessory threads, permitting it to be mounted in confined or limited access spaces. A gasket is recommended to seal the mounting location. A cover should be used to protect contacts when the connector is not in use.

MS3128

Wide Flange Wall Mount Receptacle

The MS3128 wall mount receptacle provides a wide flange for back-panel mounting, along with rear accessory threads for mounting accessories. A gasket is recommended to seal the mounting location. A cover should be used to protect contacts when the connector is not in use.

MIL-DTL-26482 Accessories

MIL-DTL-26482 Tools

MIL-26482 Solder Station

The use of a professional soldering station is the first step to ensuring connector reliability. This solder station kit provides a complete solution for terminating mil-spec style solder contacts to stranded or solid core wire. Compatible for all MIL-26482 Series 1 connectors.

MIL-DTL-26482 Specifications

- Shell Styles

- 6 Shell Styles: Plug, Wall Mount Receptacle, Box Mount Receptacle, Cable Receptacle, Jam Nut Receptacle, Solder Mount Receptacle

- Shell Sizes

- 9 Shell Sizes Are Available, Size 8-24

- Contacts Sizes

- 2 Available (#16, #20)

- Contact Plating

- Gold Plate, 50 µinches (1.27 µm) Minimum

- Max Contact Resistance

- 9 Milliohm Maximum Resistance

- Potential Voltage Drop

- <55 Millivolt Maximum Drop (Initial)

- Current Rating

- 13 Amps (Test Current) at 68°F (20°C)

- Max Operating Voltage

- 1,000 VAC (RMS) at Sea Level

- Insulation Resistance

- >5,000 Megohms at 77°F (25°C)

- Service Classes

- Inst., A, B, C, D, E

- Alternate Rotations Available

- Normal and W, X, Y, Z (if available)

- Hermetic Configurations Available

- Special Order

- Operating Temperature

- -67° to +257°F (-55° to +125°C)

- IP Rating

- Environmental IP67 Rating (Environmental Sealing)

- Salt Spray Rating

- 500-Hour Salt Spray Rating (With Olive Drab Cadmium Finish)

- Chemical Resistance

- 20 hour full immersion (unmated) in hydraulic fluid and lubricating oil without damage or material degradation

- Coupling Style

- 3-Point Bayonet, Stainless Steel Bayonet Pins, Spaced at 120° on Receptacle Shells, Ramps on Plug Coupling Ring With Locking Detent, 1/3 Turn to Couple

- Contact Arrangements Available

- 30 Standard Inserts Available

- Coupling Cycles

- 500 Minimum

- Shock

- 50g’s, 11ms Duration, Three Major Axes, 10 Microseconds Maximum Discontinuity

- Random Vibration

- 10 to 2,000Hz (15g’s), 10 Microseconds Maximum Discontinuity

- Shell Conductivity

- Maximum Shell-to-Shell Conductivity Potential Drop Less Than 200 Millivolts Across Assembly

- Insert Material

- Resilient Polychlorophrene (Neoprene) Insert, Non-Removable and Mechanically Bonded to Shell

MIL-DTL-26482 QPL Information

MIL-DTL-16482 Aliases

MIL-C-26482, MIL-26482, MIL-DTL-26482, MIL-DTL-26482H, MS26482, 26482 Series 1.