About MIL-DTL-5015 Solder Connectors

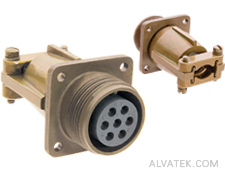

MIL-DTL-5015, formerly known as MIL-C-5015 is a standard for circular multi-pin electrical connectors used in harsh environmental conditions. The connectors themselves are also sometimes called 5015 type connectors.

The MIL-C-5015, affectionately called “Fifty-Fifteen” by most, is truly the grand-daddy of all modern military circular connectors.

These circular, threaded coupling connectors have been used in US and NATO military systems since the 1950s for general use and power applications. Connectors designated with the prefixes of MS3100, MS3101, MS3102, MS3106, MS3108 are designated to have solder terminated contacts which make them very simple to terminate with minimum of tooling requirements. Other variants of the MIL-DTL-5015 series may include front or rear release crimp contacts.

Basic Characteristics of the MIL-C-5015

Basic Characteristics of the MIL-C-5015

- Reliable and economical metal cylindrical connector

- Wide range of contact arrangements

- Simple to install with good environmental protection

MIL-DTL-5015 Solder Connector Resources

MIL-DTL-5015 Solder Connector Shell Styles

MIL-DTL-5015 connectors are IP67 rated for high-performance in critical applications. Aerospace-grade aluminum shells provide heavy-duty protection while a standard olive drab cadmium finish provides excellent corrosion resistance. Five available connector shell styles provide design flexibility for modern interconnect solutions.

Select your preferred shell style from the list below:

MS3102

Box Mount Receptacle

The MS3102 box mount receptacle has a flange for panel mounting. It is designed with a small rear profile for installation in confined spaces or where backshells are not required. The connector should be sealed with a protective cover to ensure high reliability when it is not in use.

MS3101

Cable Mount Receptacle

The MS3101 receptacle is designed for mounting on a cable or extension cord. It features an integrated waterproof wire-sealing backshell and cable clamp for strain relief. When disconnected, the receptacle should be sealed with a protective cover to ensure high reliability.

MIL-DTL-5015 Accessories

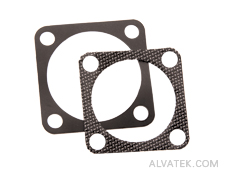

MIL-5015 Cable Bushing

MIL-5015 rubber bushings are designed to provide MS3100, MS3101, MS3106, and MS3108 connectors with additional environmental sealing. They also protect the wire jackets from friction against the strain relief clamps. Bushings of adjacent sizes are able to nest inside each other.

MIL-DTL-5015 Tools

MIL-DTL-5015 Specifications

- Shell Styles

- 5 Shell Styles: Plug, 90° Plug, Wall Mount Receptacle, Box Mount Receptacle, Cable Receptacle

- Shell Sizes

- 13 Shell Sizes are available, size 8-40

- Contacts Sizes

- 5 available (#16, #12, #8, #4, #0)

- Contact Plating

- Silver Alloy Plate, 100 100 µinches (2.54 µm) Minimum

- Max Contact Resistance

- 6 Milliohm Maximum Resistance

- Potential Voltage Drop

- 50 Millivolt Maximum Drop (Initial)

- Current Rating

- 150 Amps (Test Current) at 68°F (20°C)

- Max Operating Voltage

- 3,000 VAC (RMS) at Sea Level

- Insulation Resistance

- >5,000 Megohms at 77°F (25°C)

- Service Classes

- Inst., A, B, C, D, E

- Alternate Rotations Available

- Normal and W, X, Y, Z (if available)

- Hermetic Configurations Available

- Special Order

- Operating Temperature

- -67° to +257°F (-55° to +125°C)

- IP Rating

- Environmental IP67 Rating (Environmental Sealing)

- Salt Spray Rating

- 500-Hour Salt Spray Rating (With Olive Drab Cadmium Finish)

- Chemical Resistance

- 20 hour full immersion (unmated) in hydraulic fluid and lubricating oil without damage or material degradation

- Coupling Style

- Threaded (A-Threads), Single-Start, 4 Turns to Couple

- Contact Arrangements Available

- 126 Standard Inserts Available

- Coupling Cycles

- 250 Minimum

- Shock

- 50g’s, 11ms Duration, Three Major Axes, 10 Microseconds Maximum Discontinuity

- Random Vibration

- 10 to 2,000Hz (15g’s), 10 Microseconds Maximum Discontinuity

- Shell Conductivity

- Maximum Shell-to-Shell Conductivity Potential Drop less than 200 Millivolts Across Assembly

- Insert Material

- Resilient Polychlorophrene (Neoprene) Insert, Non-Removable and Mechanically Bonded to Shell

MIL-DTL-5015 QPL Information

Responsibility for MIL-DTL-5015 was passed to the SAE in 2000, as SAE-AS50151. Each of the individual MS part numbers or specification sheets now have SAE document numbers (a one for one transfer). So MIL-DTL-5015 has been cancelled without replacement, superseded by SAE-AS50151 specification. This specification just changed specification management to SAE organization, but connector specifications remain the same.

MIL-DTL-5015 QPL Approved Manufacturers

The following is a list of manufacturers that we can currently supply MIL-DTL-5015 Solder connectors from.

- Amphenol Aerospace

- Amphenol Connex

- Amphenol Industrial

- Array Connector

- DDK / Fujikura

- ITT / Cannon

MIL-DTL-5015 Aliases

MIL-C-5015, MIL-5015, MIL-DTL-5015, MIL-DTL-5015H, SAE-AS50151.

These connectors have also been colloquially known as simply “Cannon Plugs” or “Fifty-Fifteen”.